Where Are Distribution Cabinets Used? Powering the Modern World

If you’ve ever flipped a light switch, charged your phone, or used any electrical appliance, you’ve benefited from a distribution cabinet. These unassuming metal boxes are the unsung heroes of our electrified world, silently and safely directing power to where it’s needed most.

But what exactly is a distribution cabinet? Often called a distribution board (DB), breaker panel, electrical panel, or switchboard, it’s the central hub that takes electricity from the main supply and divides it into separate circuits. It also provides crucial protection through circuit breakers or fuses.

So, where exactly are these vital components used? The answer is: almost everywhere there’s electricity. Let’s break it down by environment.

1. In Residential and Commercial Buildings

This is where most people interact with a distribution cabinet, often without realizing it.

-

-

lighting, kitchen outlets, bathrooms, and your HVAC system. Smaller sub-panels might be used for additions like a garage workshop or a home expansion.

-

Office Buildings: A large main panel (often called a Main Distribution Board – MDB) receives power for the entire building. Then, smaller Sub Distribution Boards (SDBs) on each floor power the lighting, air conditioning, and outlets for that specific area.

-

Hotels and Restaurants: They require robust distribution systems to handle high-power kitchens (ovens, fryers), guest room electricity, lighting, and signage, all separated into organized, protected circuits.

-

Shopping Malls and Retail Stores: Large panels manage power for common areas, escalators, and elevators, while individual store tenants often have their own panels for lighting and point-of-sale systems.

Homes and Apartments: Your home’s main service panel is a classic example. It’s usually found in the garage, basement, or a utility closet. It distributes power to different circuits for

2. In Industrial and Manufacturing Facilities

-

This is where distribution cabinets get heavy-duty. Industrial environments demand robust, reliable, and often specialized panels.

-

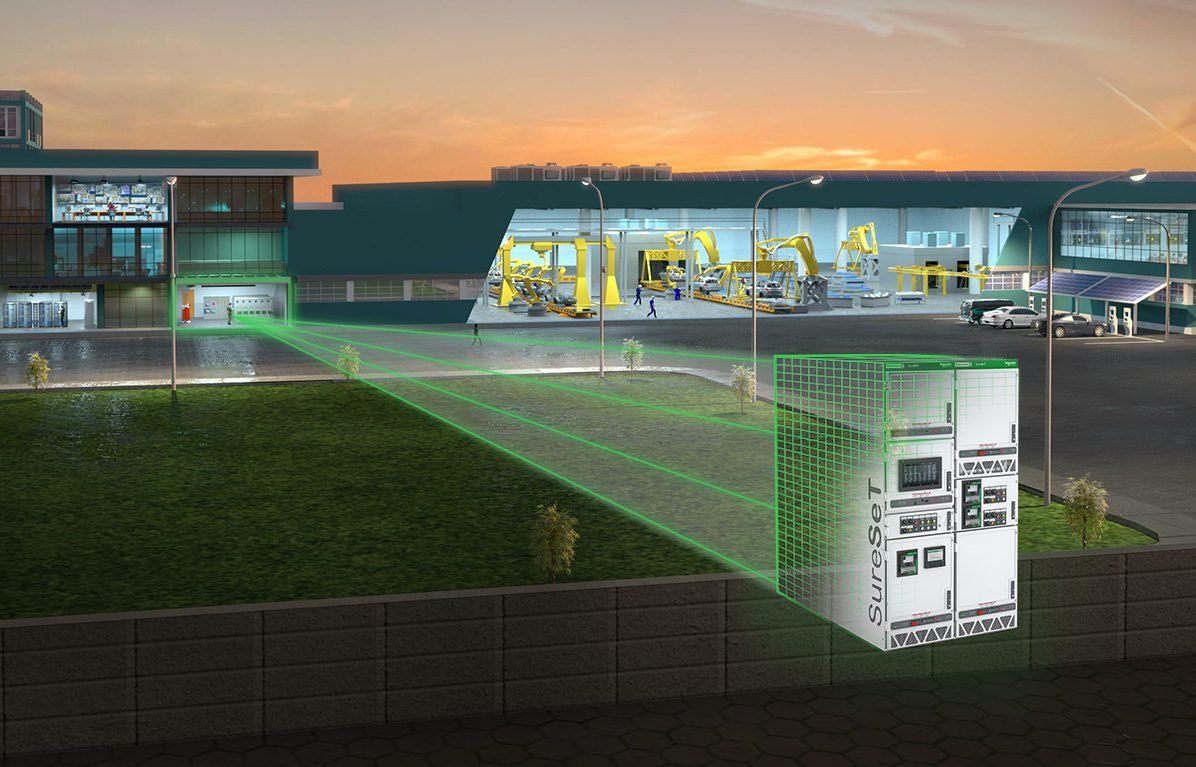

Manufacturing Plants & Factories: Here, you’ll find Industrial Control Panels (ICPs) and Motor Control Centers (MCCs). These are specialized distribution cabinets that don’t just provide power but also control heavy machinery, conveyor belts, robotic arms, and massive motors. They are built to withstand harsh conditions like dust, moisture, and vibrations.

-

Water and Wastewater Treatment Plants: Critical for powering pumps, filtration systems, aeration equipment, and control systems that run 24/7.

-

Workshops and Garages: Auto shops and woodworking shops use panels to distribute power to high-demand equipment like industrial compressors, lifts, and welders.

3. In Public Infrastructure and Utilities

Our modern infrastructure relies entirely on complex networks of distribution cabinets.

-

Data Centers: The heart of the internet requires an incredibly reliable and redundant power distribution system. Power Distribution Units (PDUs) within server racks are fed by large main switchboards to ensure servers never go offline.

-

Hospitals and Healthcare Facilities: Life-saving equipment requires absolute reliability. Hospitals use sophisticated panels with Automatic Transfer Switches (ATS) to instantly switch to backup generators during a power outage. Circuits for critical care rooms are also isolated for maximum safety.

-

Airports and Transportation Hubs: They manage power for everything from runway lights and radar systems to terminal signage, baggage carousels, and retail spaces. Safety and redundancy are paramount.

-

Schools and Universities: Distribution panels manage power across large campuses, from classroom buildings and science labs to libraries and sports facilities.

4. In Specialized and Niche Applications

-

Marine and Offshore: Ships, oil rigs, and offshore platforms use distribution cabinets built with special corrosion-resistant materials (like stainless steel or special coatings) to withstand harsh, salty environments.

-

Mining Operations: Mining requires extremely durable “mining duty” panels that are explosion-proof and designed to operate safely in potentially hazardous atmospheres with high levels of dust.

-

Renewable Energy Systems: Solar farms and wind turbines use specialized panels to combine the power generated by multiple sources (e.g., solar panels) and feed it into the main grid or a storage system.

Key Takeaway: Why They Are Everywhere

The reason distribution cabinets are used in so many places boils down to three critical functions:

-

Distribution: They efficiently divide a large incoming electrical feed into smaller, more usable circuits.

-

Protection: They house circuit breakers or fuses that automatically shut off power in case of an overload or short circuit, preventing fires and equipment damage.

-

Isolation: They allow specific circuits to be safely de-energized for maintenance and repairs without shutting down the entire power supply.

Conclusion

From the humble home basement to the most advanced data center, distribution cabinets are a fundamental component of any electrical system. They are the silent, intelligent traffic controllers of electricity, ensuring it gets where it needs to go safely and efficiently. Understanding their widespread application highlights just how critical proper design, installation, and maintenance are to our daily lives and the global economy.

-