How to Read a Switchgear SLD: Buyer’s Risk-Free Guide

Introduction

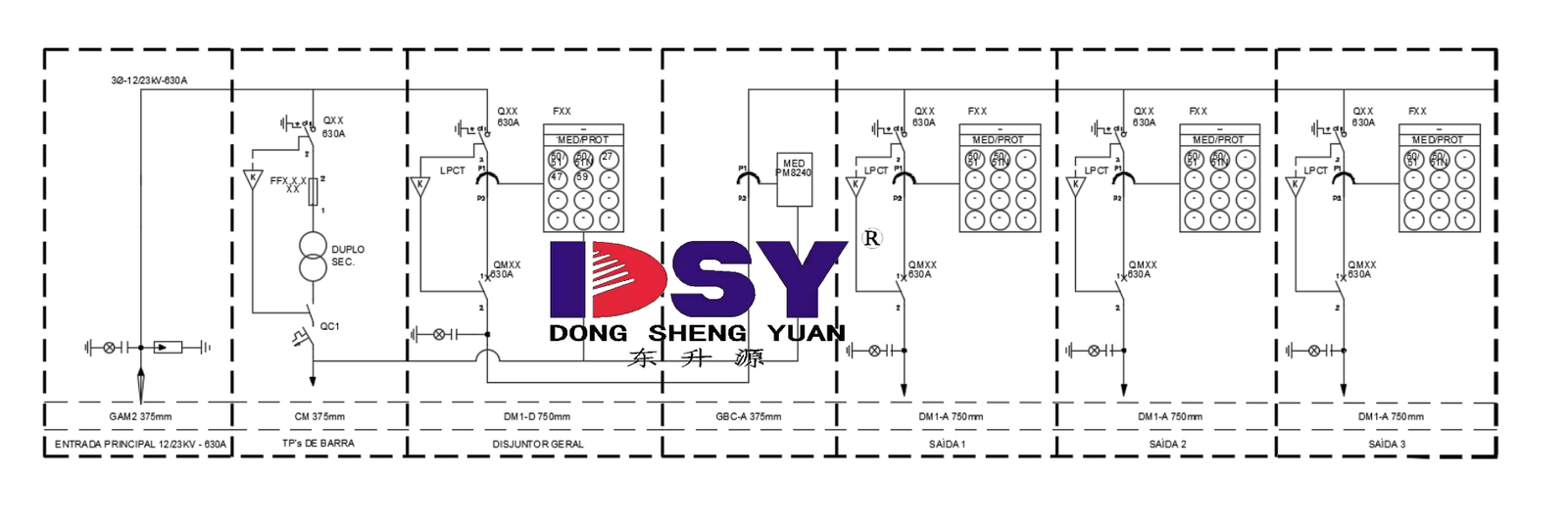

When you source switchgear, a misread single-line diagram (SLD) can lead to mismatched specifications, failed inspections, and delayed installations. As a procurement manager or industrial buyer, your responsibility goes beyond reviewing quotes—you need to ensure the vendor’s design meets your technical and compliance standards. This guide explains how to read a switchgear SLD from a procurement perspective, helping you validate drawings, reduce risk, and make smarter sourcing decisions.

What Is a Switchgear Single-Line Diagram (SLD)?

An SLD presents your electrical system’s architecture in a simplified, standardized format. It condenses critical data—such as equipment ratings, power flow, and protection devices—into a single reference document. For procurement teams, the SLD serves as a contract-level blueprint. Misinterpreting it can mean approving non-compliant gear or receiving panels that don’t fit your site.

Why It Matters During Procurement

- Verify system layout before issuing a PO

- Cross-check specs against your project’s technical requirements

- Assess protection logic and coordination

- Ensure compliance with standards like IEC 62271, IEC 60617, ANSI C37.2

Key Elements Procurement Should Review

Standard Symbols You’ll Encounter

| Component | What It Represents | What to Confirm in Procurement |

|---|---|---|

| Circuit Breaker | Main isolation/protection device | Voltage/current rating matches RFQ specs |

| Busbar | Power distribution backbone | Material, current rating, insulation type |

| CT/VT | Metering and protection transformers | Ratio, accuracy class, location in SLD |

| Isolator | Disconnection for maintenance | Mechanical interlock and earthing presence |

| Grounding | Safety path for faults | Proper grounding layout shown |

Tip: Always request a legend or annotated diagram from the vendor.

Layout Flow & Labeling

- Trace from the power source to loads

- Confirm voltage levels match your system (e.g. 11kV, 400V)

- Check feeder naming aligns with your load schedule or site plan

Buyer Alert: If labeling is unclear, clarification delays your approval process.

Step-by-Step: How to Review a Vendor’s SLD

Step 1: Confirm Power Source and Direction

Check whether the incoming supply is clearly shown. Ensure direction of power flow is intuitive and matches your system expectations.

Step 2: Validate Equipment Ratings

- Voltage (kV/V): Must align with tender spec

- Current (A): Should match load requirements

- Short-circuit rating (kA): Match with utility fault levels

Why it matters: If any rating is too low, FAT will fail; if too high, cost overruns are likely.

Step 3: Verify Protection Scheme

Ensure relays, CTs, arc sensors, and metering are shown. Each should serve a clear protective function.

Buyer Tip: Ask the vendor if the relay settings and coordination study are included in their deliverables.

Step 4: Check Redundancy and System Flexibility

For critical systems (e.g. data centers), verify:

- Dual busbar systems

- Transfer switches

- Maintenance bypasses

Procurement Note: These features often impact delivery time and cost—ensure they’re part of your scope.

Common Pitfalls to Watch For

| Issue | Risk for Buyers |

|---|---|

| CT/VT symbol confusion | Incorrect metering or failed relay logic |

| Missing arc flash protection | Incomplete compliance with NFPA 70E |

| Overlooked grounding strategy | Safety failures or certification rejections |

| Misaligned breaker ratings | Equipment overload or failed site tests |

| Incomplete title block | Unapproved or outdated drawings slip through |

Action: Include SLD review in your internal technical checklist before placing the order.

Use the SLD to Strengthen Your RFQ Process

An accurate SLD helps you:

- Compare technical clarity across multiple vendors

- Pre-screen for design errors before engineering review

- Build trust by aligning technical expectations early

Ask for the SLD during the quotation phase—not after contract signing.

Conclusion

If you’re approving switchgear drawings without understanding the SLD, you’re risking project overruns, safety failures, and rework. But with a clear review strategy, you’ll spot mismatches early, confirm compliance, and hold vendors accountable.

Call to Action

Need help reviewing a vendor’s SLD or preparing one for your RFQ?

Contact our technical team now — we’ll help you validate specs, flag compliance gaps, and avoid costly surprises. Learn more about our Switchgear Technical Support Services or explore related resources on our blog.