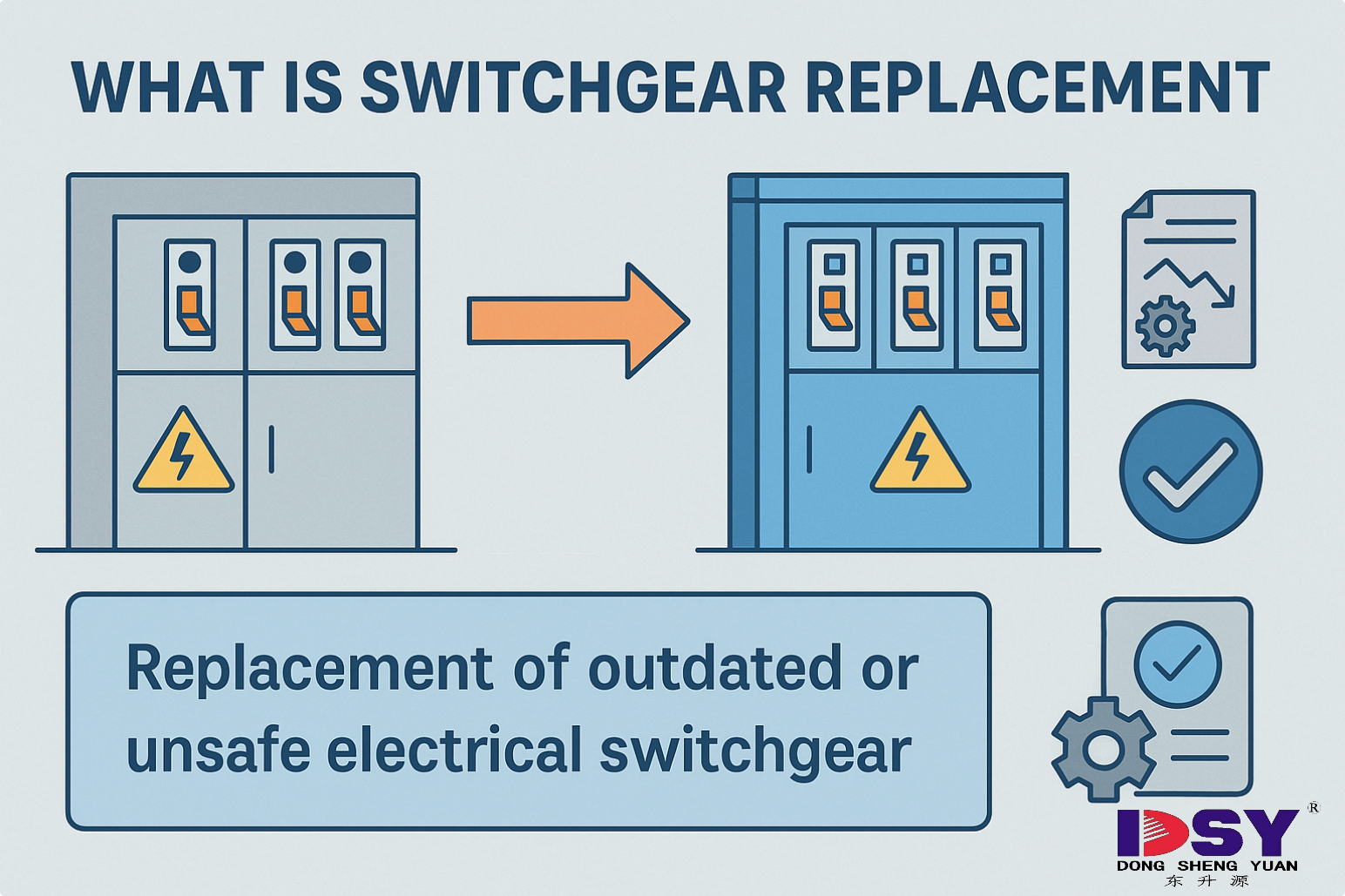

What is Switchgear Replacement?

Switchgear replacement is the process of upgrading outdated electrical systems to newer, safer, and more efficient models. It’s often essential for ensuring operational safety and meeting compliance standards.

This process helps eliminate safety risks, improves energy efficiency, and supports modern smart monitoring capabilities.

Why Does Switchgear Need to Be Replaced?

Old Age and Mechanical Wear

Switchgear systems typically last 20–30 years. Aging equipment increases the risk of failure, overheating, or system blackouts.

Safety Standard Compliance

Modern switchgear must comply with IEC 62271 or IEEE C37 standards. Non-compliant gear poses legal and operational risks.

Limited Load Capacity

As facilities expand, older systems may not support the increased power load, leading to overheating or tripping.

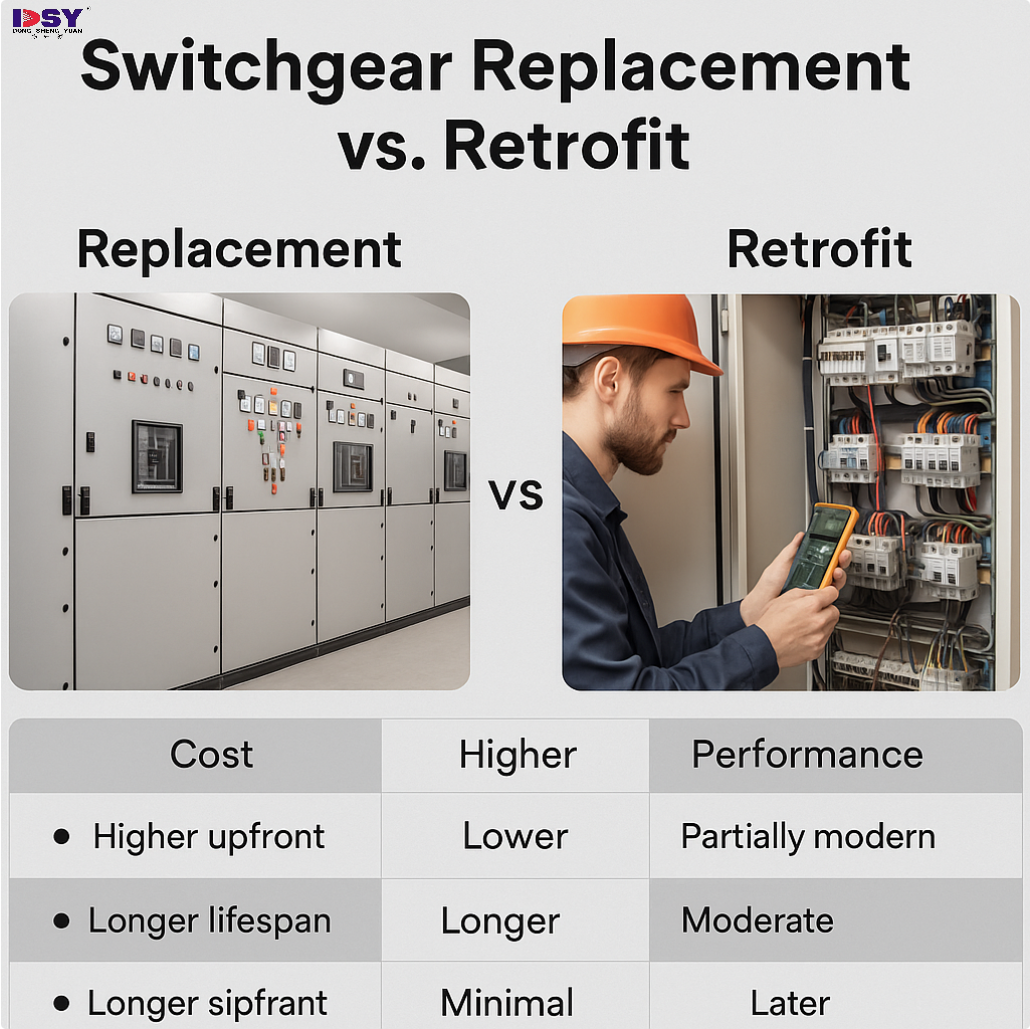

Switchgear Replacement vs Retrofit

Replacement involves full removal and installation of a new gear, while retrofitting updates key components. Each has its advantages.

| Factor | Replacement | Retrofit |

|---|---|---|

| Cost | Higher upfront | Lower upfront |

| Performance | Fully optimized | Partially modern |

| Longevity | Longer lifespan | Moderate |

| Downtime | Moderate | Minimal |

Steps in the Switchgear Replacement Process

Inspection and Assessment

Qualified technicians evaluate current systems, looking for overload, aging, or wear.

System Design

New gear is designed to meet voltage, current, and space requirements.

Installation & Testing

Old switchgear is safely removed. New equipment is tested for insulation resistance, current protection, and operation.

Choosing the Right Switchgear

Options include air-insulated switchgear (AIS) and gas-insulated switchgear (GIS). Key considerations include:

-

Operating environment (indoor/outdoor)

-

Space availability

-

Voltage level and frequency

DSY’s Switchgear Replacement Solutions

Dongshengyuan (DSY) offers medium voltage switchgear built for industrial upgrades and retrofits.

Features include:

-

AIS, GIS, and hybrid options

-

Compliance with IEC, ISO, and IEEE

-

Remote diagnostics and smart safety systems

Learn more at dsyswitchgear.com

Or explore global standards at IEEE Switchgear Standards (external link)

FAQs

Q1: What is switchgear replacement?

Upgrading electrical switchgear systems to meet modern performance and safety needs.

Q2: What’s the lifespan of switchgear?

Typically 20–30 years, depending on the environment and maintenance.

Q3: How do I know if I need a replacement or a retrofit?

If the system is outdated or non-compliant, full replacement is safer. Retrofitting is suitable for partial upgrades.

Q4: What are DSY’s advantages?

Global technical support, smart-compatible designs, and certified switchgear.

Conclusion

Switchgear replacement ensures electrical safety, system reliability, and future readiness. With DSY, businesses can confidently upgrade to high-performance, certified systems.