Switchgear for Outdoor Use: Choose the Right Model & Avoid Failures

Introduction

As a procurement manager, you face high stakes when sourcing switchgear for outdoor projects. If you choose a unit that can’t handle extreme weather, corrosion, or temperature swings, you risk shutdowns, safety violations, and spiraling maintenance costs. This guide helps you select outdoor switchgear that performs reliably under harsh conditions—so you avoid regrets later.

Outdoor Protection Essentials: Enclosure Ratings, Materials & Climate Control

Outdoor reliability depends on more than just a “weatherproof” label. As a buyer, you must assess how enclosure design, material quality, and thermal features work together to resist real-world threats like salt fog, UV, heavy rain, and temperature swings.

- Enclosure Ratings: Demand IP65–68 or NEMA 4X/6P to protect against water ingress and dust. For U.S. or coastal markets, UL 1558 compliance is a must to meet safety and endurance standards.

- Material Selection: If you’re sourcing for coastal, chemical, or industrial areas, insist on 316L stainless steel or galvanized steel with powder coating. Always request ASTM B117 salt spray test data and IEC 60068 UV test results for long-term durability.

- Climate Adaptability: In hot, humid, or high-altitude environments, require passive ventilation, solar shielding, or built-in heaters and fans. Sites above 1000m need derating tables per IEC/IEEE standards to avoid overload or insulation failure.

Neglecting any of these areas could result in corrosion, arc faults, or insulation breakdown—forcing unplanned replacements and audits. Always ask for certified testing—not just product brochures.

Compare Switchgear Types: Know What You’re Paying For

| Type | Procurement Benefits | Procurement Risks | Use Cases |

|---|---|---|---|

| GIS | Sealed, compact, low maintenance | Higher cost, SF₆ gas handling | Desert, coastal, or offshore plants |

| AIS | Lower upfront cost | Exposed parts, poor weather resistance | Semi-enclosed, indoor setups |

| Metal-Clad | Arc-safe, modular, widely supported | Larger footprint, ventilation needed | Industrial refineries, large sites |

| Pad-Mounted | Compact and tamper-proof | Limited in customization | Utility distribution, roadside systems |

Arc Safety Compliance: Avoid Legal and Financial Exposure

Arc flash incidents are both dangerous and expensive. Before signing off, verify your outdoor switchgear meets:

- ANSI C37.20.7: Ensures tested arc fault containment.

- NFPA 70E Labeling: Clarifies PPE zones and safe access areas.

- Grounded Interlocks: Prevent accidental live access and protect personnel.

Failing to confirm arc safety compliance increases injury risk, insurance premiums, and liability exposure.

Don’t Overlook These Technical Ratings

Under-specifying technical ratings leads to overloads, downtime, or system failures. Check these before issuing a PO:

- Voltage & Current: Always apply a 20% safety margin above your operating load.

- SCCR: Should handle short circuits of at least 25kA in utility-scale or industrial zones.

- BIL: Match the impulse withstand rating to your region’s lightning and surge risk.

- Mechanical Life: For remote or unmanned sites, demand 10,000+ operation cycles.

Insist on Real-World Testing & Certification

Don’t settle for theoretical specs. Confirm the gear is field-proven under similar outdoor stress:

- ASTM B117 (salt fog) and IEC 60068 (UV exposure)

- Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) reports

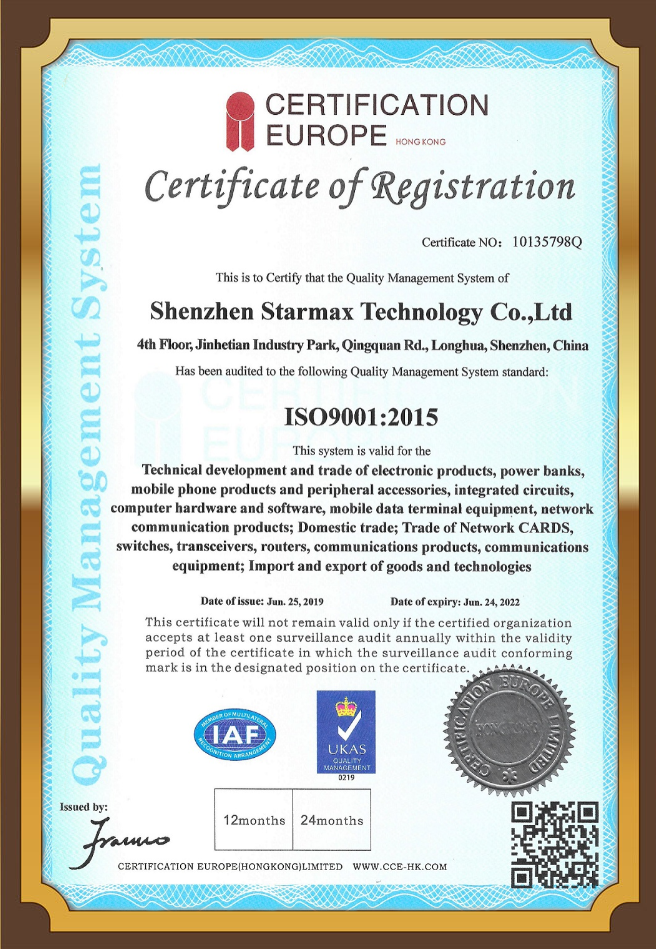

- IEC 62271, UL 1558, and ISO 9001 certifications

Conclusion

Outdoor switchgear failures are costly, avoidable, and often due to poor specification at the procurement stage. By asking the right questions, verifying certifications, and aligning features to your site’s risks, you protect uptime, avoid compliance issues, and reduce lifecycle costs.

Contact Us

Looking for rugged, tested, and certified switchgear for outdoor environments? Contact our engineering team now to request specs, drawings, or a tailored quote.