What Is Switchgear & Why Is It Essential for Modern Power Distribution Systems?

Discover how switchgear enhances safety and uptime—and learn how to choose the right type for your project or facility upgrade.

1. Understanding Switchgear: The Backbone of Your Power System

Switchgear isn’t just about turning power on or off—it’s your facility’s first line of defense against electrical failures. It houses disconnect switches, fuses, circuit breakers, and relays to isolate faults and maintain operational safety.

- Ensures safe maintenance without shutting down the whole system

- Prevents cascading failures in mission-critical operations

- Improves protection coordination across transformers, cables, and loads

For Buyers: Evaluate not just the technical specs, but whether the switchgear design supports quick fault location, selective isolation, and remote diagnostics—key for reducing unplanned downtime.

2. Types of Switchgear: Choose by Voltage and Environment

2.1 Based on Voltage Level

| Type | Voltage Range | Ideal For |

|---|---|---|

| Low Voltage (LV) | ≤ 1kV | Retail, small commercial systems |

| Medium Voltage (MV) | 1kV – 36kV | Industrial plants, data centers, and renewable farms |

| High Voltage (HV) | > 36kV | Utility substations and transmission lines |

Buyer Note: Don’t overspec. Using HV gear in an MV project may result in unnecessary complexity and higher installation and maintenance costs.

2.2 By Insulation Type

- Air-Insulated (AIS): Economical, easier to service—but requires more space

- Gas-Insulated (GIS): Compact and sealed—ideal for space-constrained or dusty environments

- Vacuum Switchgear: Common in MV; offers arc control and low maintenance

Real-World Guidance: Urban projects often favor GIS due to its footprint. For outdoor or remote use, AIS with arc-flash containment is a safer long-term investment.

3. What Should Be Inside a Reliable Switchgear Assembly?

- Modern circuit breakers with remote tripping and protection curves

- Relays compatible with SCADA or IoT systems

- CTs and PTs are properly sized for metering or protection roles

- Clear busbar segregation and access for maintenance

Common Mistake: Inadequate sizing of CT/PT can cause metering errors or mis-trip issues. Always match spec to site load profiles.

4. Why Smart Buyers Trust Switchgear for System Continuity

4.1 Safety that Goes Beyond Basics

Arc-resistant designs and interlocked enclosures protect operators from serious injury, vital in process industries and confined substations.

4.2 Operational Resilience

With properly segmented switchgear, localized faults don’t shut down entire operations—ideal for critical systems like data centers or hospital power backups.

4.3 Energy Optimization

Modern switchgear allows for energy audits, real-time metering, and load forecasting—key for cost-saving and ESG reporting.

4.4 Renewable Compatibility

MV GIS with fast fault clearing and back-feed protection is crucial when integrating solar, wind, or BESS into your power architecture.

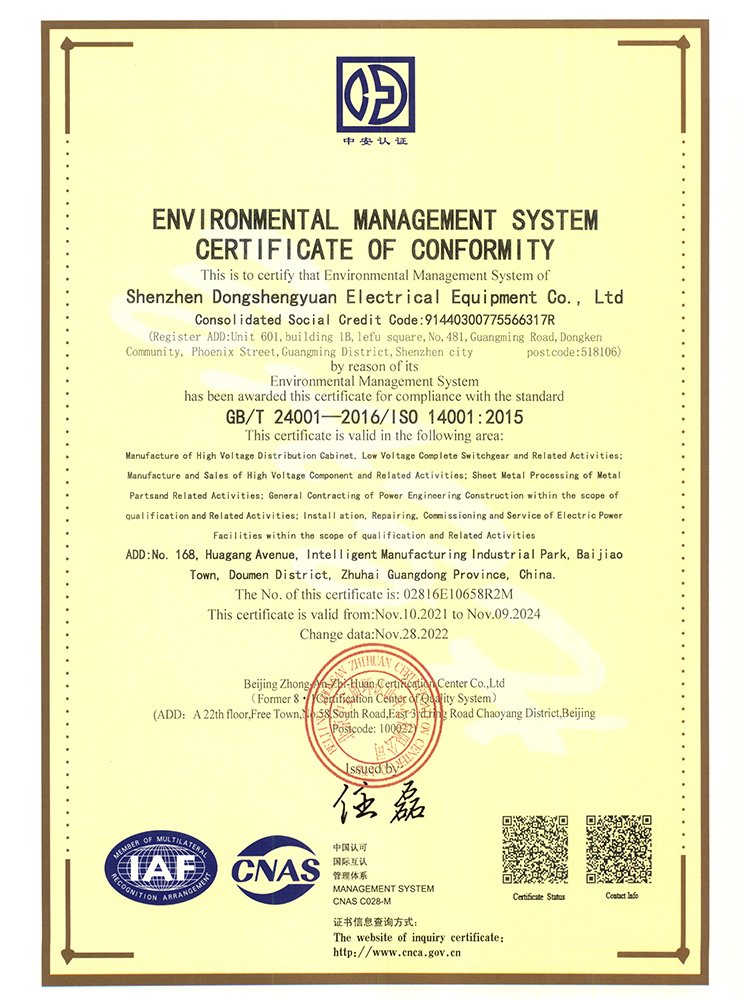

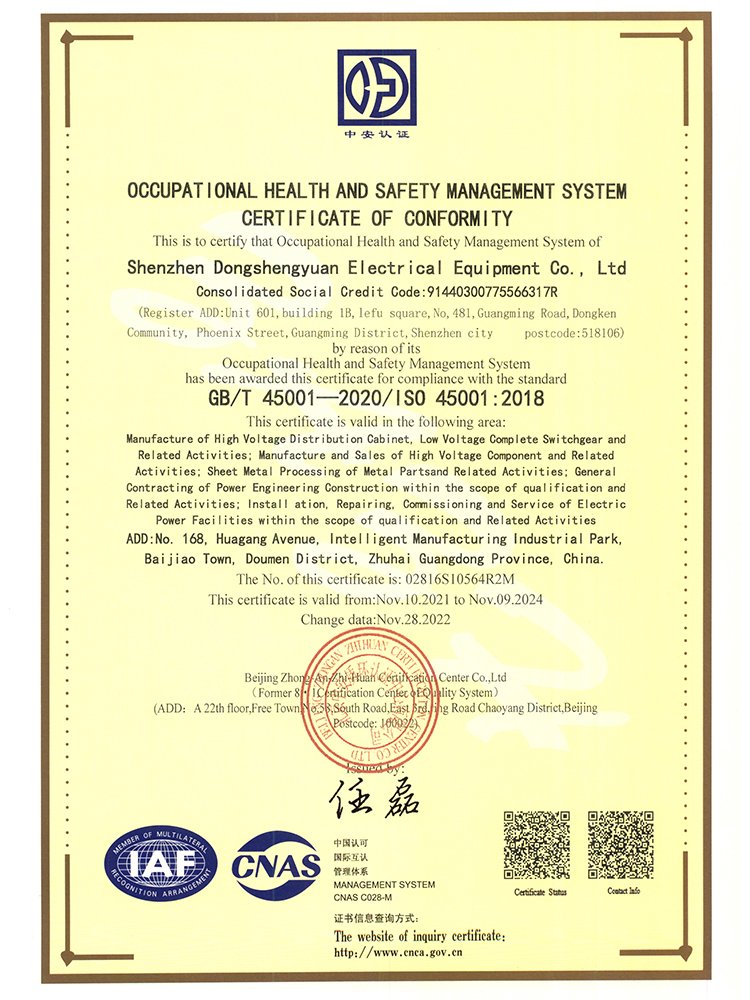

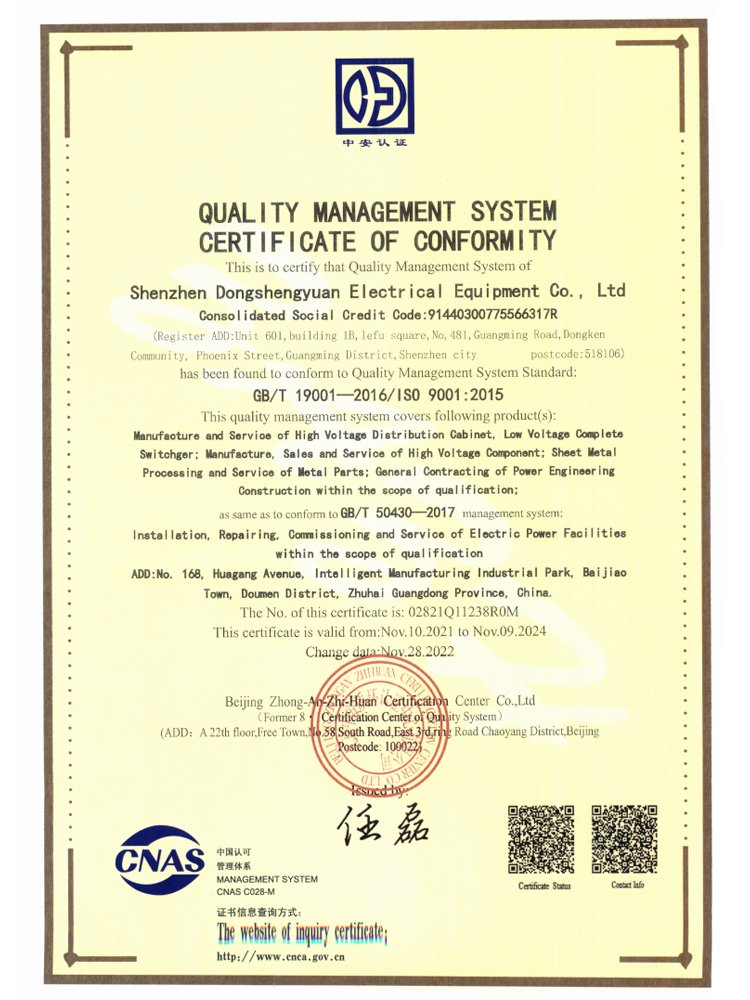

5. Certifications That Matter in Global Procurement

- IEC 62271 – Mandatory for medium and high voltage switchgear

- UL 1558 / UL 67 – Often required for U.S. or export projects

- ISO 9001 / 14001 / 45001 – Reflects reliable manufacturing processes

Tip: Before issuing RFQs, ensure the supplier’s certifications match the utility or EPC firm’s compliance checklist in your target region.

6. Applications by Industry—And the Risks of Poor Fit

- Utilities: HV GIS reduces footprint but requires trained service teams

- Factories: AIS is easier to service but may be vulnerable to dust/moisture

- Solar/Wind Plants: MV vacuum switchgear minimizes fault propagation

- Data Centers: Modular switchgear with 100% uptime switchover essential

Case Example: A Saudi-based 50MW solar project adopted compact MV GIS switchgear from DSY, cutting floor space by 35% and reducing outage events by 90%.

7. Trends B2B Buyers Should Watch

- Partial discharge monitoring to prevent insulation breakdown

- Green insulation alternatives (like g³) are gaining utility approval

- Pre-engineered modular switchgear for fast-track infrastructure

Procurement Insight: Ask your supplier if digital twin simulation or factory pre-test data is available—available-this shortens commissioning time.

8. Buyer Checklist: How to Specify the Right Switchgear

- Match the voltage class to the load and future expansion (avoid overdesign)

- Check IP and IK ratings against site conditions (dust, heat, rodents?)

- Choose insulation based on footprint and maintenance strategy

- Verify all certifications upfront—don’t rely on verbal claims

- Ask about warranty terms and the availability of spare parts globally

What’s at Stake? Selecting the wrong switchgear can lead to thermal overloads, unexpected trips, unscalable systems, and regulatory penalties.

9. Frequently Asked Buyer Questions

- Can I use LV switchgear in a solar PV project?

Only for small-scale inverters. For utility-scale systems, MV switchgear with protection relays is essential. - What’s the difference between switchgear and switchboards?

Switchgear provides protection and control; switchboards are basic power distribution points. Don’t confuse the two for critical loads. - How often should I maintain switchgear?

Typically, every 12 months, but harsh or high-load sites may require more frequent inspections.