Why Data Centers Need Medium Voltage Switchgear

Introduction

For data centers, unplanned downtime is not an option. Core priorities like power reliability, regulatory compliance, and scalable capacity are make-or-break for operations. Medium Voltage (MV) switchgear serves as the linchpin in delivering on these priorities. This guide breaks down the critical role of MV switchgear in data centers, key considerations for procurement teams, and strategies to mitigate project risks through informed selection.

The Critical Role of Power Infrastructure in Data Centers

Why Uptime Is Non-Negotiable

Data centers pursuing Tier III or Tier IV certifications face severe consequences for even brief outages—including costly SLA violations and irreversible damage to brand reputation. MV switchgear is instrumental in maintaining power redundancy and operational continuity, directly addressing uptime requirements.

Energy Intensity and Associated Challenges

Modern data centers are among the most energy-intensive facilities, demanding power distribution networks that minimize transmission losses, optimize physical space, and support growing load demands without compromising efficiency.

What Is Medium Voltage Switchgear?

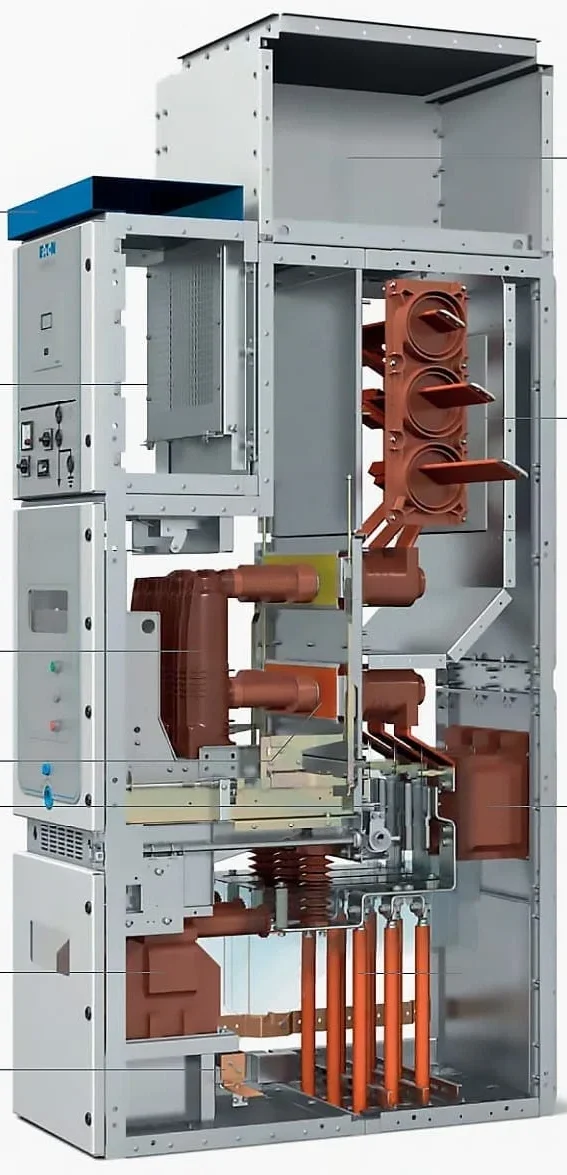

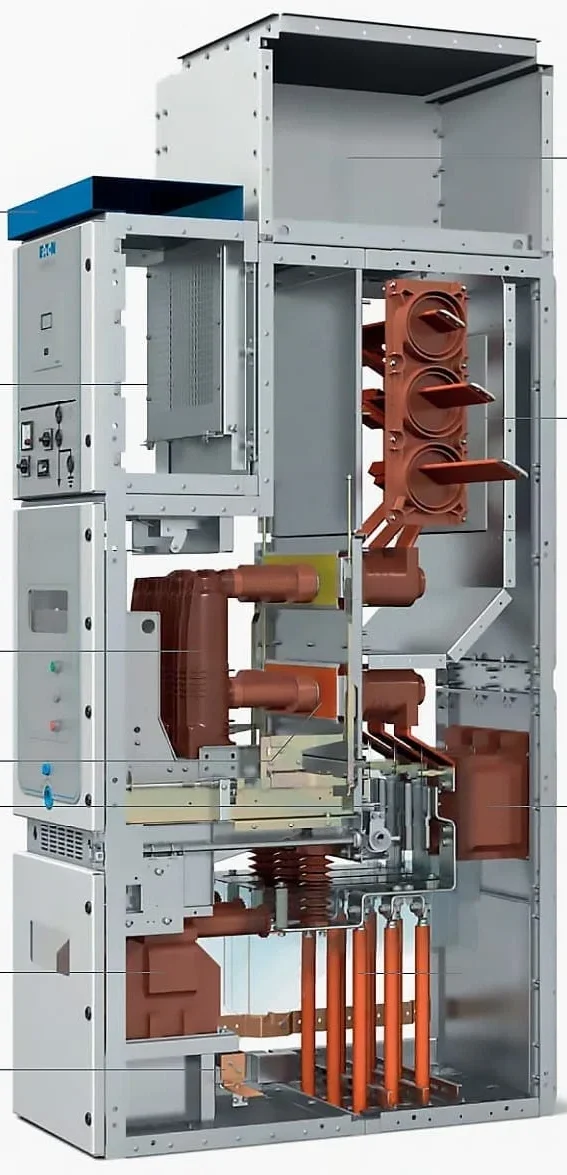

As the backbone of data center power distribution, MV switchgear operates within the 6.6 kV to 36 kV range. It integrates essential components—including circuit breakers, busbars, protective relays, and safety devices—housed in robust, metal-enclosed systems to manage and protect high-voltage power flow.

Why Data Centers Depend on MV Switchgear

- Reliability: Redundant feeder configurations eliminate single points of failure, ensuring power continuity during component or line issues.

- Safety: Built-in arc flash mitigation and compliance with IEC/ANSI standards protect on-site personnel and equipment from hazardous incidents.

- Scalability: Modular designs allow for seamless capacity expansion, adapting to increasing IT load demands without full infrastructure overhauls.

- Efficiency: MV systems reduce line losses compared to low-voltage (LV)-only setups, lowering energy waste and operational costs.

- Compliance: Aligns with global standards from organizations like the Uptime Institute and IEC 62271, ensuring regulatory adherence.

Medium Voltage vs. Low Voltage Distribution

| Evaluation Criteria | MV Switchgear | LV Distribution | Benefits of Choosing Right | Risks of Choosing Wrong |

|---|---|---|---|---|

| Footprint Efficiency | Compact design for high-load applications | Expansive footprint at scale | Maximizes usable data center space for IT hardware or redundancy systems, boosting facility density and reducing the need for costly expansions. | Wastes critical floor space, restricts IT growth, and may force unplanned facility expansions—adding capital costs and project delays. |

| Energy Losses | Minimal transmission losses | Significant losses over long distances | Lowers monthly electricity bills by reducing waste; decreases heat output, cutting HVAC energy use and extending equipment lifespan. | Drives up operational costs; excess heat increases cooling demands and raises the risk of unplanned outages due to overheating. |

| Cost Profile | Higher upfront CAPEX, lower total cost of ownership (TCO) | Lower upfront CAPEX, higher ongoing OPEX | Delivers long-term financial stability by minimizing operational and maintenance costs, offsetting higher initial investment within 3–5 years for most facilities. | Leads to unsustainable long-term costs; frequent repairs, high energy bills, and premature replacements result in TCO overruns. |

| Downtime Risk | Mitigated via built-in redundancy | Elevated risk without MV integration | Meets Tier III/IV uptime targets (99.982%–99.995%), avoids SLA penalties, preserves customer trust, and eliminates data loss risks. | Triggers costly SLA breaches; disrupts customer services, erodes brand loyalty, and requires expensive recovery efforts. |

Key Procurement Considerations

- Verify compliance with international standards (IEC, ANSI, UL) and local utility grid codes to avoid regulatory gaps.

- Clearly define technical specifications: short-circuit current rating, insulation type (SF₆ or dry air), and relay protection logic.

- Mandate Factory Acceptance Testing (FAT) and valid type test certificates to ensure performance meets design requirements.

- Assess vendor capabilities: lead time reliability, global service network, and availability of spare parts for long-term maintenance.

- Prioritize digital-ready models with real-time monitoring (IoT-enabled sensors, remote diagnostics) for predictive maintenance.

Cost & Lifecycle Value (TCO)

While MV switchgear requires a larger initial capital investment, its lifecycle benefits far outweigh the upfront cost. Reduced energy losses, minimized downtime, and lower maintenance needs translate to 20–30% lower TCO compared to LV-only systems over a 10-year period. For procurement teams, focusing on TCO—rather than just CAPEX—ensures long-term operational and financial resilience.

Conclusion

At its core, data centers rely on MV switchgear to deliver the reliability that underpins their operations. By prioritizing compliant, technically aligned solutions and partnering with reputable vendors, procurement teams can secure uptime, reduce lifecycle costs, and build facilities that adapt to future energy demands.

Get Custom MV Switchgear Solutions

Looking for certified, scalable MV switchgear tailored to your data center’s Tier rating and load requirements?Contact us today.